Temperature controlled shipping without polystyrene:

We ship in recycled packaging made from renewable raw materials

In Germany and Austria, we have gradually converted our shipping logistics for frozen and refrigerated goods for you: Instead of the usual polystyrene (“styrofoam”) insulation boxes, we now use shipping boxes with hemp insulation.

The insulation is made of fibers from European industrial hemp. Hemp is a real natural talent with an exemplary eco-balance. The hemp plant grows up to 4 cm every day, binds a huge amount of CO2, improves soil fertility and is almost completely recyclable.

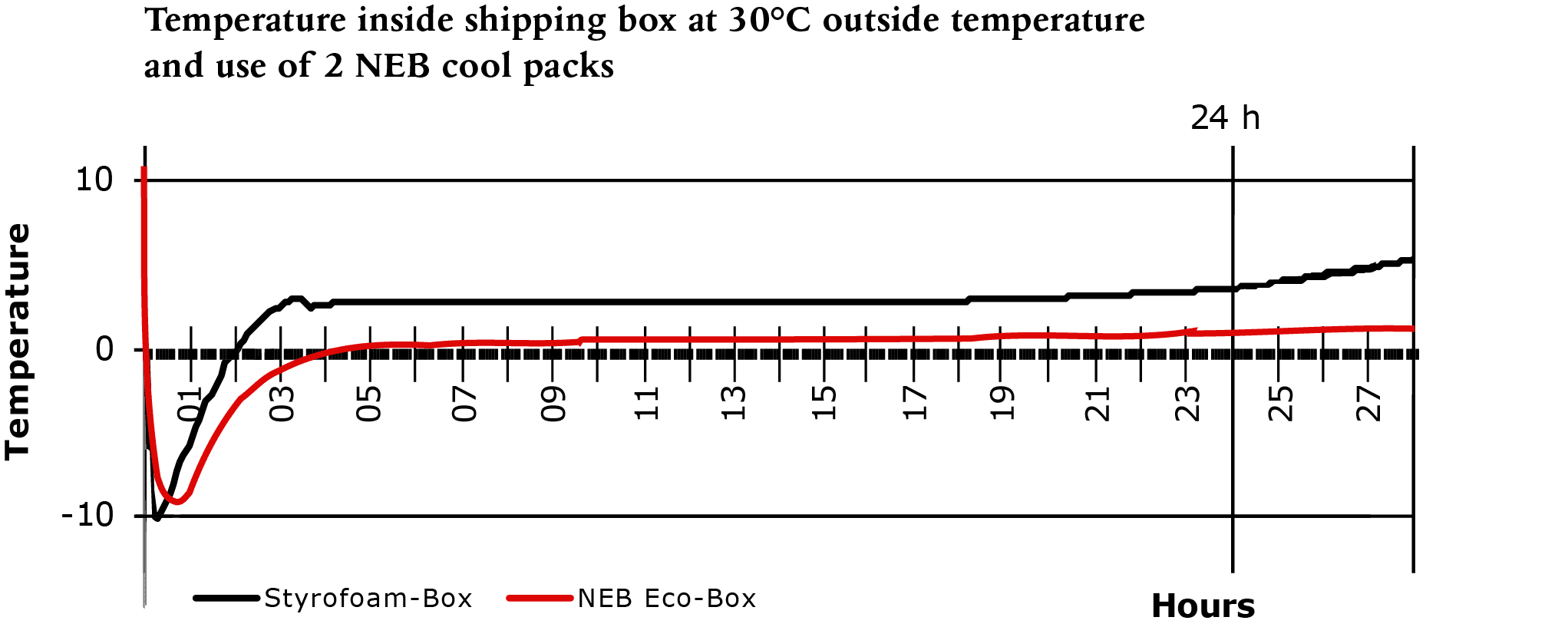

This new insulated box meets the strictest criteria for reliable shipping:

- Functional: shock-absorbing, moisture-regulating and very good insulating properties

- Ecological: made from 100% renewable raw materials from sources in Europe

- Pure: pure, thermally treated hemp fibres in food quality

- Tested: best insulation performance tested according to internal and external standards

- Certified: tested and certified according to high hygienic standards

(DIN EN15593, GMP-Verordnung (EG) Nr. 2023/2006, (EG) Nr. 1935/2004)

Please dispose of cardboard with your local recycling program. The insulation panels are compostable and can be disposed of with your organic waste. But as a creative scientist, you may have even better ideas, whether for a decorative DIY, as plant protection in winter or as bedding for your pet rat. Feel free to share your ideas with us!

Do you have any questions or remarks?

free call: 0800/246-5227 (in Germany)

free call: 00800/246-52277 (in Austria)

e-mail: infe.de@neb.com

Do you already know our NEBees?

In collaboration with the Walkmühle beekeeping, we have been managing three beehives in Frankfurt am Main since 2023. Our bees are true multitaskers: they pollinate plants, produce honey, and our beekeeper explains the interconnections of ecosystems to Frankfurt’s children through our bees.

NEB has become a certified B Corporation

„Using business as a force for good”

NEB is excited to announce that it has become a Certified B Corporation™, a recognition awarded to organizations with the highest standards for social and environmental performance, transparency and accountability. B Corp™ certification goes beyond evaluating a product or service; it looks at the overall impact of a company by evaluating how a company treats its employees, customers, its community and the environment

A pioneer in environmental stewardship:

We have used recycled paper since 1975

Did you know that the first NEB catalog in 1975 was printed on recycled paper already? “Science should not be done at the expense of the environment!” – an attitude that has been deeply rooted at NEB ever since the company was founded. The effort to keep our ecological footprint as small as possible is considered in all economic decisions made.

All our printed products such as catalogs, posters and brochures are made from certified environmental protection paper!

We use recycled paper and/or paper fibers from sustainable forestry, bleached without chlorine. Our local printing office is also certified for environmental protection and uses environmentally friendly inks and coatings, mostly of natural origin.

compensation for CO2 that we cannot yet avoid

NEB supports climate and environmental projects

For many years, NEB has been implementing CO2 compensation for our print products such as catalogs, brochures, or posters. With the help of our partner company “Climate Partner,” we calculate all the CO2 emissions that unavoidably occur in the process chain and offset them through recognized climate protection projects. In the past, we have supported projects for the protection of chimpanzees and gorillas in Central Africa, the establishment of wind and solar parks, as well as marine conservation efforts.

With the production of the 2025/25 catalog, we are supporting two projects for the protection of peatlands in Germany and the transition to clean energy by women in rural India.

#1630 Protecting moorland in Germany

This project supports the protection of existing peatlands in Germany and also promotes the renaturation of drained peatlands. Intact peatlands store large amounts of CO2 and are an important habitat for endangered animal and plant species.

#1617 Women in India are driving the transition to clean energy

The project gives women in rural India access to solar lights and water filters. The use of solar lights and water filters significantly reduces CO2 emissions and reduces impact on local forests as less firewood is needed.

Organic PE-Foil

Made from renewable raw materials and recyclable

At New England Biolabs we send our customer magazine “NEB-Aktuell”, our catalogues or other special prints and brochures in a protective organic PE foil – if possible bundled with several printed materials in one delivery.

We use a PE foil made from sugar cane. It has identical properties to traditional foils of fossil origin (crude oil) but is made from a bio-based, renewable raw material and is 100% recyclable. If the PE foil is not recycled directly via the PE recycling stream, it is completely decomposed into water and CO2 when thermally re-used by waste incineration.

Because not all organic products are the same

What are the differences?

Bioplastics are a group of different plastics with very different properties. However, they must always meet at least one of two “bio” criteria.

Biobased

Biobased means that at least part of the plastic consists of renewable, i.e. vegetable raw materials, e.g. sugar, starch, oils, cellulose, etc.

Biodegradable

Biodegradable means that the plastic can be degraded by naturally occurring microorganisms. This produces water, CO2 and a small amount of biomass. Bio-based plastics can be biodegradable, but do not have to be.

Bioplastics in comparison

Bioplastics:

Green PE foils (used by NEB) are bio-based and 100% recyclable, but not biodegradable. The raw material used is chemically identical to standard PE quality and therefore provides identical mechanical properties. However, since the raw material used for the production of the raw material is non-fossil (no crude oil), but bio-based and renewable (sugar, starch, cellulose…), Green PE film is much more sustainable than conventionally produced PE films. When used thermally, Green PE breaks down into water and CO2 without further residues.

Biodegradable foils are bio-based and completely biodegradable under industrial composting conditions. The raw material used is PLA. The mechanical properties of biodegradable films are worse than those of PE or Green PE films. The modified raw material also gives the film an unmistakable optical and haptic “biofeeling”. For many applications, e.g. garbage bags, etc., the properties are absolutely sufficient, but not for use in postal dispatch.

Oxo-degradable is not “bio”.

Oxo-degradable or oxo-degradable plastics are often wrongly referred to as bioplastics. But they are anything but “bio”. Materials such as cobalt, manganese or iron are added to these plastics. Under the influence of UV light, heat and oxygen, the polymer chains are dissolved and the material decomposes into minute particles. In contrast to biodegradable plastics, however, there is no complete decomposition of the plastic by microorganisms. Although the plastic is no longer visible to the eye, it is still present and represents a major problem in our ecosystem in the form of microplastics. It is also foreseeable that oxo-degradable films will be banned in the EU due to their negative properties.

Summary

| biodegradable | Green PE (as used by NEB) |

Standard PE | |

|---|---|---|---|

| biobased | yes | yes | no |

| bio-degradbable | yes | no | no |

| recyclable | yes | yes | yes |

| mechanical properties | + | +++ | +++ |

| applicable as bag | yes | yes | yes |

| shrink films | no | yes | yes |

| foils for automation | no | yes | yes |

| approved by logistics carrier | no | yes | yes |

A small step with a strong impact

NEB goes for energy-saving LED lighting

In cooperation with our partner Green Vision, the lights at New England Biolabs were replaced by energy-saving and sustainable LED lamps. Compared to the conventional, mercury-containing fluorescent tubes previously used, the environmentally friendly light sources promise a 3-fold longer lifetime in conjunction with a lower energy consumption.

Environmental Commitment

We do not only focus on minimal environmental impact when shipping our products or manufacturing and packaging our brochures.

Already during the development and production processes at New England Biolabs, Inc. in the US, special attention is paid to maximum energy efficiency and environmental protection. This includes an intelligent, sustainable building design, a waste management and recycling program, including a waste water treatment plant, and the use of solar energy.

With the Labconscious Blog we have created an information platform that can help you to make laboratory work more environmentally friendly. Here you will find a number of tips on how to avoid plastic waste, save energy in the laboratory and other aspects of environmental protection.

Environmental stewardship is one of the founding principles of NEB. Learn more about our efforts at neb.com .

Sustainability, environmental protection and social responsibility.

Download brochure as PDF

Code of Conduct for Suppliers

Download PDF!

Further information can be found in our Technical Resources section or at neb.com. Information on trademarks can be found here.